As a tech-savvy individual, you’ve likely observed a surge in discussions surrounding solar PV cells. Additionally, an increasing number of people are embracing the role of independent energy generation at home.

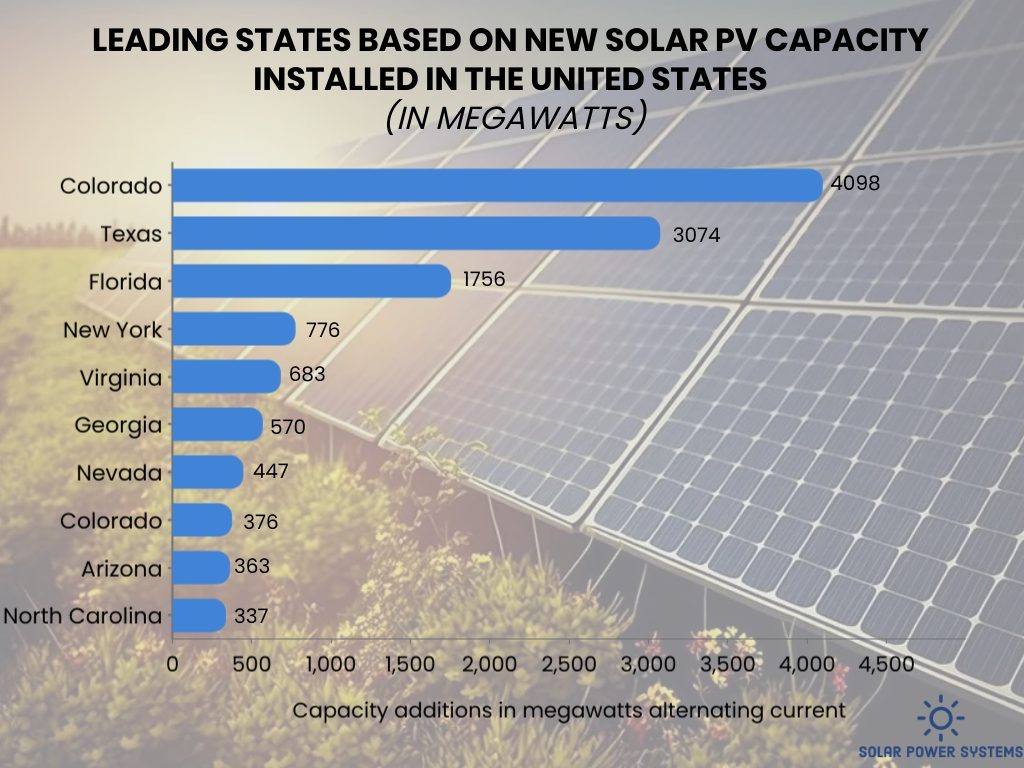

The National Renewable Energy Laboratory estimated that around 3.9 million residential solar systems were installed in the USA in 2022 alone. According to Statista, California and Texas emerged as unbeatable leaders.

What is the secret behind the popularity of green energy? The confluence of pressing global challenges, such as climate change, financial and energy crises, has propelled a surge in curiosity for renewable energy sources.

But what about the construction of solar cells? What materials and processes are used in their manufacturing? What are the key solar cell components? Don’t rely on luck; find out more from the experts at Solar Power Systems to choose the best solar system for your needs.

Key Points about Solar PV Cells

Solar PV cells are one of the sources of renewable energy that helps reduce our dependence on fossil fuels.

In reality, batteries are just a small element of a solar complex. When connected either in parallel or in series, these individual solar photovoltaic cells form a solar panel, serving as the fundamental building block of the entire system.

The solar cell function is to convert solar energy into electrical current for various purposes. The most common ones include:

- Energy production for domestic or industrial use.

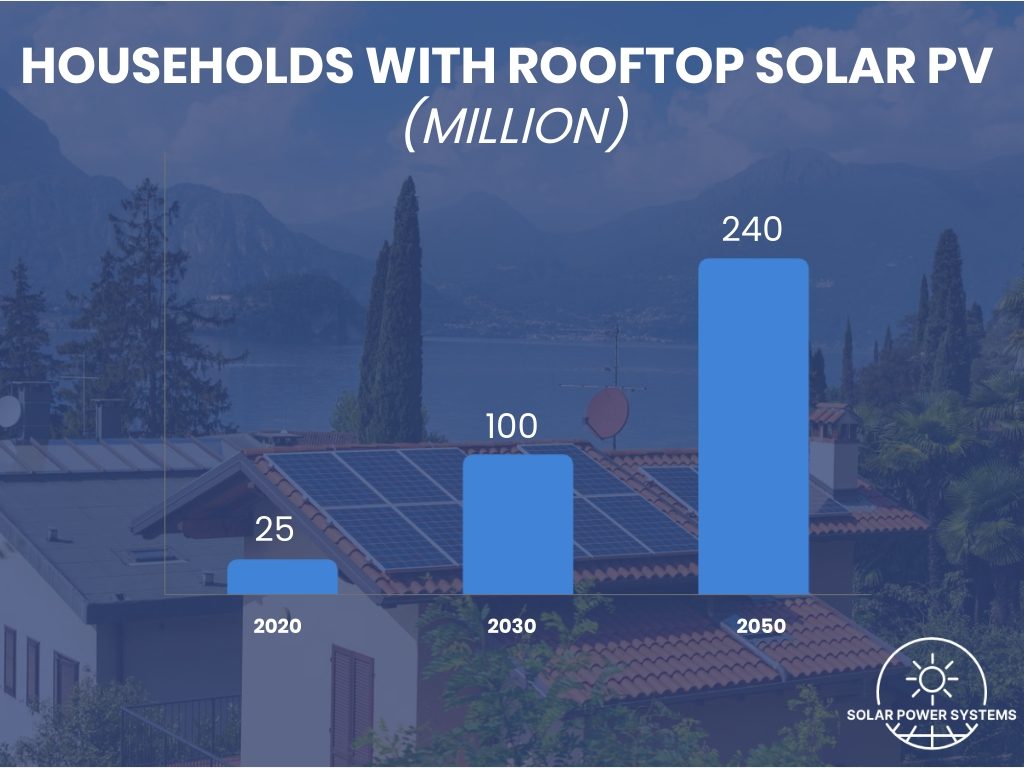

In 2022 alone, it reached 1293 TWh, a 26% increase from 2021. IEA predicts that the number of households with solar PV from 2020 to 2050 will increase by 860%.

- Charging electric vehicles, household, or industrial devices.

About 4% of Americans own an electric vehicle, and a third of them charge it at home using solar photovoltaic cells.

There is a common misconception that solar PV cells cease functioning during winter due to shorter days and reduced sunlight intensity. While it’s true that batteries generate less energy in winter, it is essential to clarify that solar cells operate efficiently year-round regardless of the season. Solar cell efficiency, averaging 15-20%, measures the ratio of sunlight received to energy generated.

Main Types of Solar PV Cells

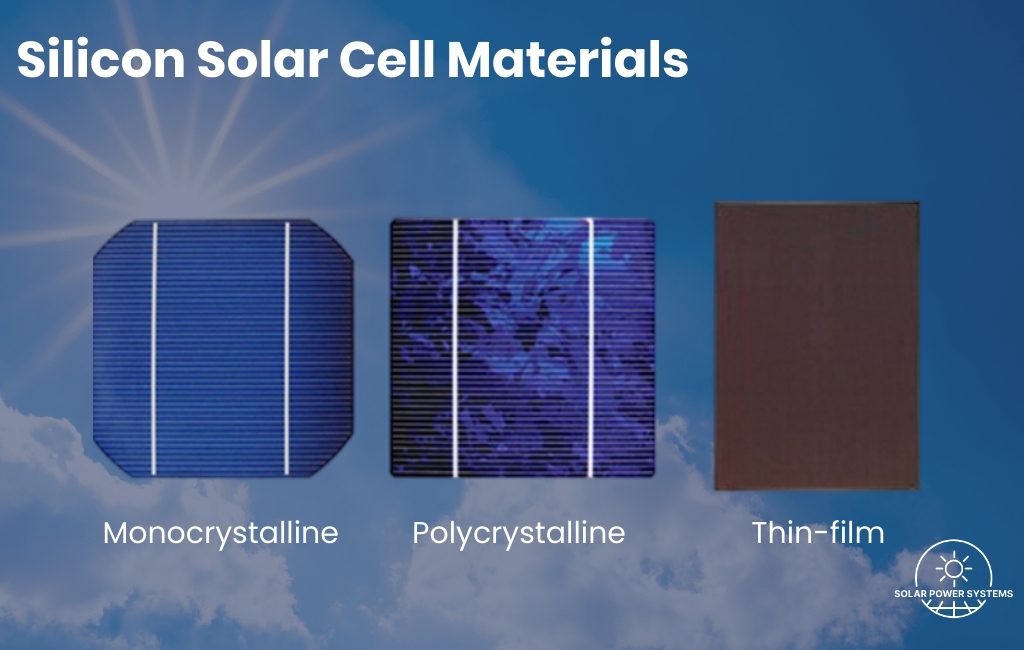

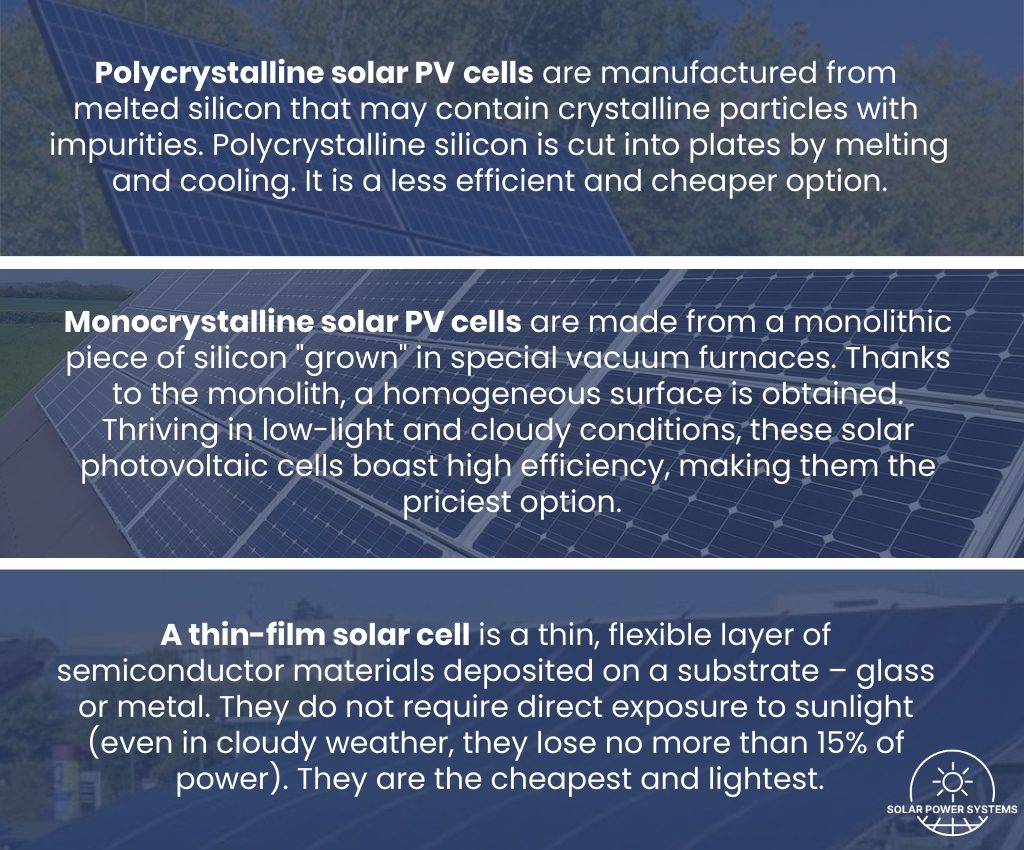

Presented below are the primary categories of solar photovoltaic cells:

The most popular solar cell materials are those where silicon serves as the primary material. As a semiconductor, it conducts electric current, exhibiting high electrical and thermal conductivity to convert solar energy into electricity and dissipate the generated heat in the energy conversion process.

Therefore, the type of battery is determined by the principle of silicon application. According to this, we distinguish polycrystalline, monocrystalline, and thin-film batteries.

All types of solar PV cells are popular on the market, with the choice depending on the installation site. For example, thin-film cells occupy twice the area, so they are more commonly used in large enterprises. Monocrystalline cells, due to their lightness and compactness, can bend slightly, making them suitable for installation on uneven surfaces.

Structure of Solar Cell

Explore the structure of a solar cell to assess its potential as an energy source and choose the best model for your needs.

Let’s take a closer look at the main components, relying on the solar cell diagram.

1. Aluminum Frame

The frame serves to protect the internal components of the battery and provides a sturdy structure for installing the solar PV cells panel.

Popular frames are made of aluminum, with the IMARC Group forecasting a market growth rate of 10.6% by 2028. Anodized aluminum, with increased corrosion resistance, is crucial for batteries installed outside buildings.

The aluminum frame performs several important functions:

- Protecting solar elements from damage, impacts, and atmospheric influences (wind, rain, snow).

- Shaping the battery and ensuring both stability and reliable operation.

- Facilitating heat dissipation from solar elements.

The frame thickness is 1-2 mm, and the width varies depending on the size of solar PV cells.

2. Tempered Glass

Tempered glass is produced by heating regular glass to high temperatures and then cooling it. This process creates tiny cracks in the glass, enhancing its strength. Consequently, glass ensures the durability of the solar cell, acting as a shield against debris, precipitation, or extreme temperature changes.

In the event of damage caused by external factors, tempered glass differs from regular glass by breaking into small, harmless glass particles instead of sharp fragments, thanks to the presence of microcracks.

Despite the typically 2 to 4 mm thickness of tempered glass, there are no issues with permeability. Glass has low sunlight reflection and anti-glare features on the back, allowing even more sunlight to reach the solar elements. In 2022, 61% of all solar PV cells were highly transparent.

3. Layer of Transparent EVA Film

The coating layer in a solar cell is a flexible and thin layer of ethylene-vinyl acetate (EVA) material applied to the surface of the battery’s photodiode. The sheet is made of a thermoplastic polymer, ensuring:

- Corrosion resistance

- Durability

- Good light transmission

- Insulation properties.

Additionally, the coating layer provides a strong connection between tempered glass and solar elements.

The thickness of this layer is crucial – too thin would inefficiently absorb sunlight, and too thick would hinder the movement of electrons. The thickness varies depending on the battery type; for thin-film-based solar PV cells, it can be a few micrometers.

4. Solar Photovoltaic Cells

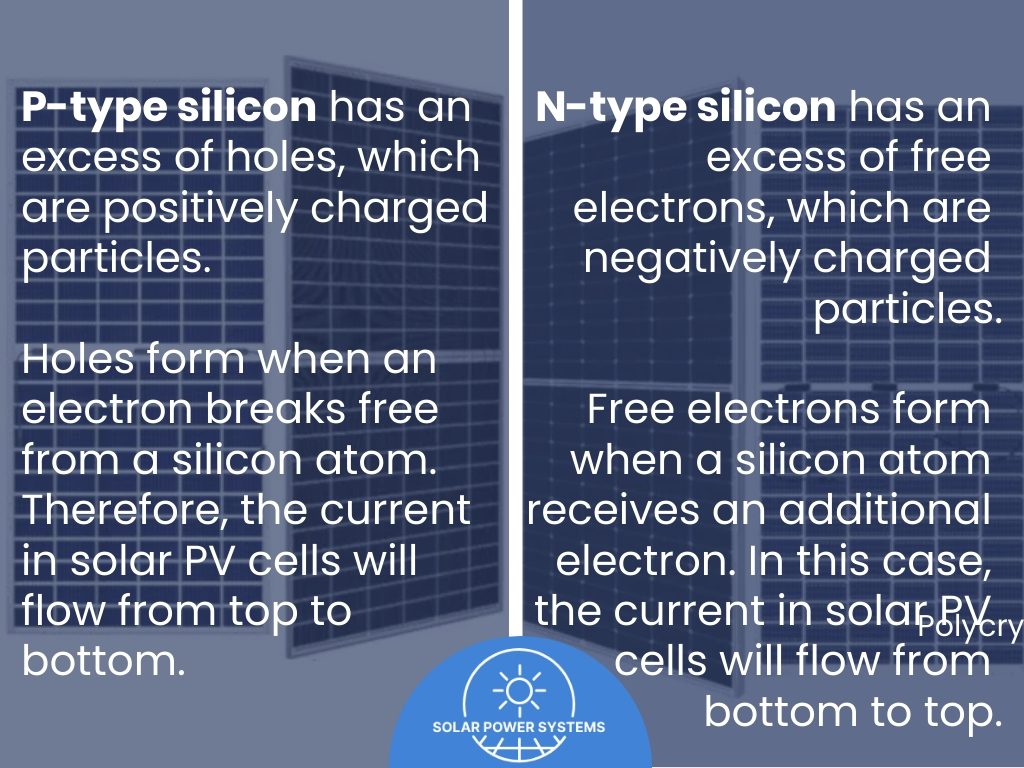

Solar PV cells consist of two types of semiconductor solar elements – p-type and n-type silicon. The difference lies in the type of charge carriers.

An electric field forms between the two semiconductor layers. When a photon of sunlight knocks a free electron loose, the electric field pushes it out of the silicon junction. This process creates an electric current.

It’s important to highlight that n-type silicon offers improved resistance to corrosion and external influences, and it is expected to result in a 3% increase in energy production efficiency compared to p-type silicon.

5. Distribution Box with Connection Block

A photovoltaic distribution box is a sealed device designed for easy and reliable connection of solar cables to panels, the converter, and the external circuit.

It is located on the backside of the solar cell, where the connection of all components takes place. This includes the transition from photovoltaic elements to electrical wires, which subsequently lead to the controller.

To ensure protection against short circuits, make sure that it is:

- Placed in a dry, not excessively humid location.

- Subjected to systematic cleaning from debris and dirt.

The output wires of solar PV cells are connected to the internal wires in the distribution box, and the internal ones are connected to external cables. Bypass diodes in the box ensure the normal operation of components when sunlight is insufficient.

Notable benefits of the distribution box encompass minimal forward voltage and power losses, coupled with a high current-carrying capacity.

Working Principle of Solar Cell

Now that you know about the components of a solar cell, we can summarize its working principle by going through each point.

- The aluminum frame, as the external part of the battery, protects internal components from environmental influences.

- Tempered glass, as the top layer of solar PV cells, protects against changing weather conditions and maximizes the penetration of sunlight.

- The EVA film provides additional protection for solar elements and helps keep them in a certain position.

- Solar elements of p-type and n-type silicon, the so-called heart of the battery, generate electric current due to the flow of electrons caused by sunlight hitting the surface of solar PV cells.

- The distribution box with a connection block collects the current from solar elements and directs it to the inverter, which converts DC to AC.

The solar cell working principle is based on the internal photoelectric effect – the formation of an excited electron-hole pair at the p-n junction. Excess electrons in the n-type and a shortage in the p-type create a flow. Photons striking the silicon semiconductor release electrons from the n-layer, captured by the p-layer, and as electrons move in a circular path, they lose energy, charging the battery.

Exploring Solar Cells: Structure, Efficiency, and Operation

Solar photovoltaic cells are truly wonders of energy with enormous potential to provide a clean and accessible energy source. However, before buying and installing a solar system, remember the specifics of the components of solar cell – the aluminum frame, glass, EVA film, solar elements, and the distribution box. Choose only the best!

Don’t miss the unique opportunity to join the solar revolution. Visit our blog, where you’ll find answers to your questions.

Frequently Asked Questions

How does the photoelectric effect phenomenon work in a solar cell?

Photons coming from the sun knock electrons out of silicon atoms, which then form a current flowing from the p-n junction to the external contacts of the solar panel cell.

Is the EVA film resistant to temperature changes?

Yes, it can protect the solar cell construction even at temperatures up to 150°C.

What is the lifespan of solar photovoltaic cells?

The solar panel cell has a long service life – over 25 years.